1 Comment

Luis Vargas

3/12/2024 05:49:34 pm

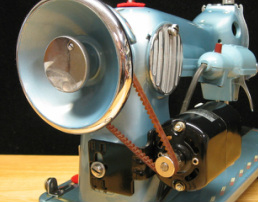

One way to increase the power of a motor, if necessary, is to connect a rectifier diode source to convert alternating current to direct current. This makes the universal motor more Efficient and more powerful

Reply

Leave a Reply. |

News, Reviews,

|

RSS Feed

RSS Feed