|

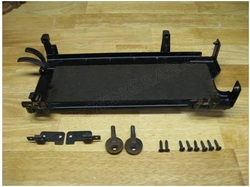

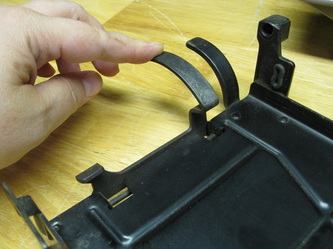

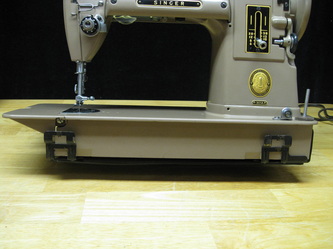

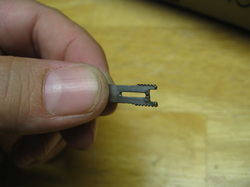

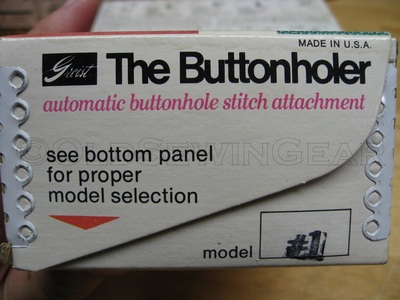

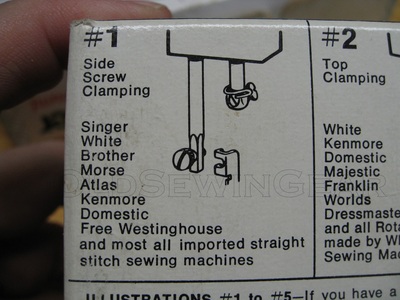

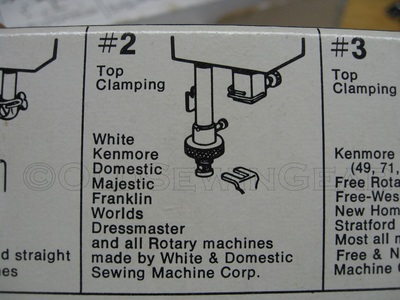

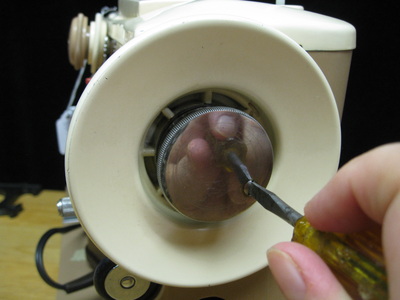

I'm finally back in the sewing room and my latest project calls for long decorative ruffled strips. How tedious...sigh... Hold on, didn't Singer make an attachment for that? I'm embarrassed to admit that after all these years of loving, refurbishing, and selling these machine I never actually took the time to learn how to use the ruffler. Time to correct that omission. So today I pulled out my sewing machine manual and learned something new. And let me tell you, the ruffler is a pretty nifty little gadget. As always, I am amazed at how Greist and Singer found ways to make repetitive sewing tasks simple, precise, and fast. Here's what it looks like: So now we've seen it, but how does it work? I could try to describe it, but it's so much better to see it in action.

So there you have it - how to use a ruffler. I'm honestly shocked that I never tried it before. It's actually very easy to use and the results are beautiful. Why not give it a try! Happy Sewing! Barbara OldSewinGear...dedicated to helping you get the most out of your old sewing gear.

10 Comments

|

News, Reviews,

|

RSS Feed

RSS Feed