4 Comments

Sak

1/13/2015 01:38:19 am

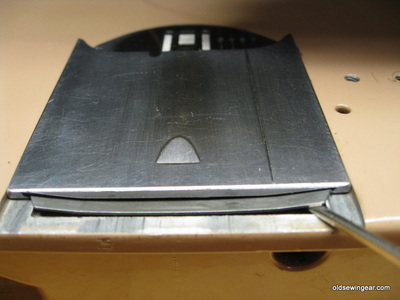

Thanks, Barbara. This works perfectly. Except the screw holding the broken spring has, you guessed it, been replaced with something that doesn't have a slot for a screw at the back. Not sure what to do, unless I could somehow chisel a screw slot into the back of the screw! Ugh.

Reply

Sak

2/11/2015 02:23:06 am

Continuing saga of the broken spring: the screw has no slot, but I have found a repair shop that will take it apart and re-time it for 60 dollars. I figure while its undone, I should replace the screw so I don't run into this next time. But where can I find that screw with the slot in the front and the back? And what is it called while I search? Any ideas? Thank you in advance.

Reply

OldSewinGear

2/11/2015 10:40:27 am

So sorry to hear you're still struggling with what should have been a very simple repair. I don't know of any magic source for the split screw, so my recommendation would be to check with a local machinist to see if they can fabricate one for you. Hope this helps, Barbara

Reply

April

4/10/2020 10:34:05 am

I got this sewing machine when my MIL passed. I don't know if it was in working order or not but pulled it out last night, followed along to set but basic setting (straight stitch, utility foot, etc) and I noticed it needed a needle. Loosen and put a universal needle in from the box of assorted 'sewing stuff" I also received (placing the flat part to the back) and it either isnt able to be placed deep enough or it is hitting something underneath the plate. Two broken needles later I'm searching for answers. LOL. Help :)

Reply

Leave a Reply. |

News, Reviews,

|

RSS Feed

RSS Feed